Dressing Systems

We have a comprehensive range of dressing systems that can be retro-fitted to your machine to give a rotary dressing action to enable superabrasives wheels to be dressed.

Brake Truing Device

Designed for truing and dressing diamond and CBN wheels quickly and effectively with minimal superabrasive loss.

The brake truing device uses a silicon carbide abrasive wheel to dress larger resin bonded diamond and CBN wheels – the engineered braking system ensures a well trued and dressed wheel.

High Frequency Dressing Unit

We provide a range of high frequency (HF) dressing spindles complete with a convertor for precise accuracy when setting the rotary speed of the diamond dresser. This allows for precise control over the dressing of small internal and highly accurate vitrified CBN grinding wheels.

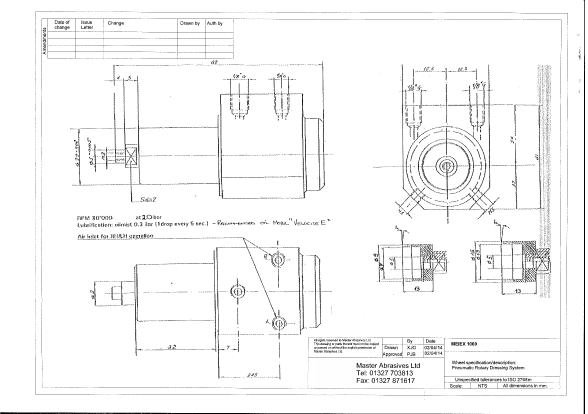

Pneumatic Dressing Spindle

As an alternative to the HF dressing spindles we offer a lower cost pneumatic dressing spindle – this is not as controllable as the HF units but does give a rotary action to ensure successful dressing of vitrified CBN internal grinding wheels.