Micromatic Grinding Technologies

We offer a full range of external, internal, universal and special purpose cylindrical grinders in CNC, PLC and hydraulic versions by Micromatic Grinding Technologies.

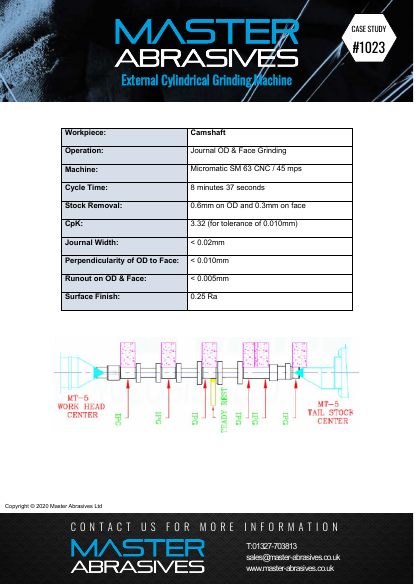

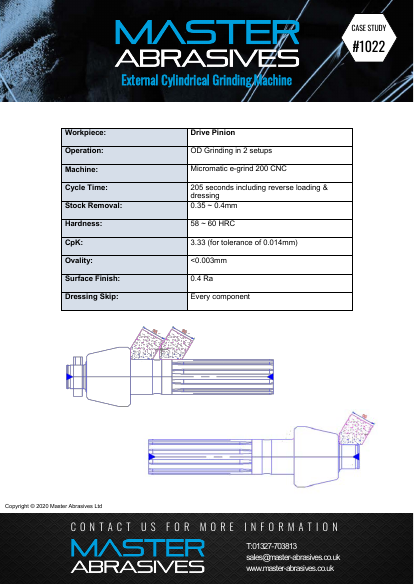

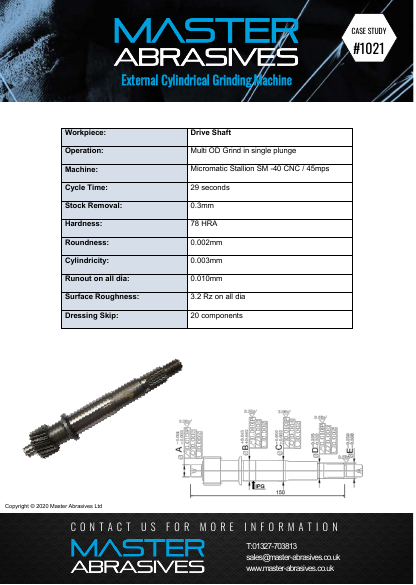

Cylindrical Grinding Machines

Eco 200 Grinding Machine

In the hydraulic machine range, the compact model eco 200 is designed for grinding of small size high-precision components for tool room and small batch production. This grinding machine is suitable for:

- External grinding

- Internal grinding

- Face grinding

We have this model set up for demonstration in our grinding and finishing showroom. Please contact us to arrange a visit for demonstration.

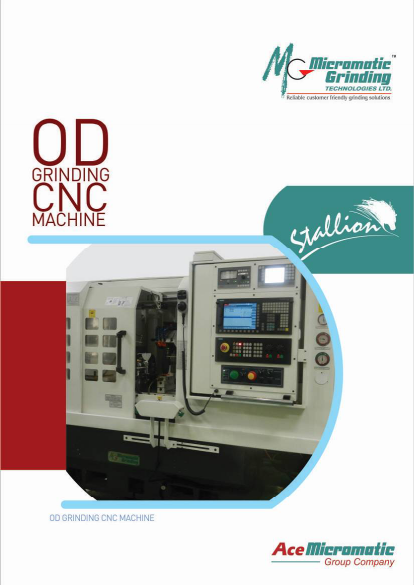

PLUTO-18 CNC Grinding Machine

PLUTO-18 is a CNC grinder specially designed by Micromatic Grinding Technologies for:

- Compactness and high-performance

- Highly accurate small components

- Both plunge and traverse grinding operations

- Total productive maintenance” (TPM) friendly

- Adaptability for factory automation

We have the PLUTO-18 available for demonstration in our grinding and finishing showroom. Please contact us to arrange a visit for demonstration.

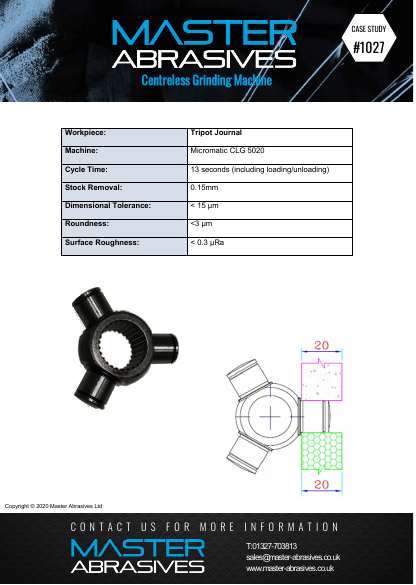

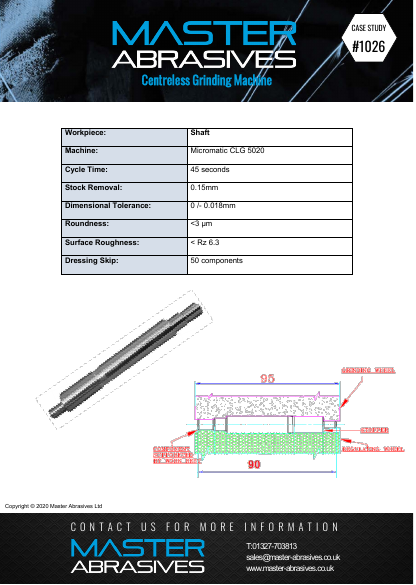

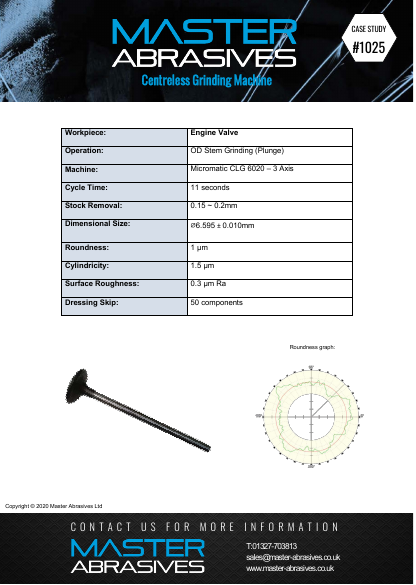

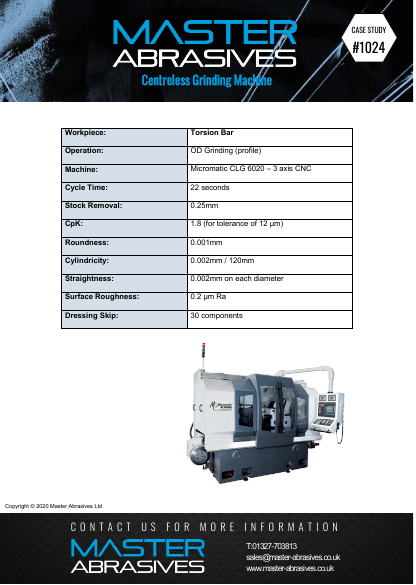

Centreless Grinding Machines

A range of production CNC Centreless Grinders have also been added to expand the range of machines manufactured by Micromatic Grinding Technologies.

Key features of these grinders include:

- Suitable for higher productivity and accuracy

- Ideal for large batch production

- Configured for both through-feed & in-feed grinding.

- Various types of automation can be integrated with the machine for parts such as engine valves, U-J cross, piston pin, shocker tube, hydraulic valve spool and others.

Please download the Micromatic Centreless brochure for more information on machines available and specifications or contact us.

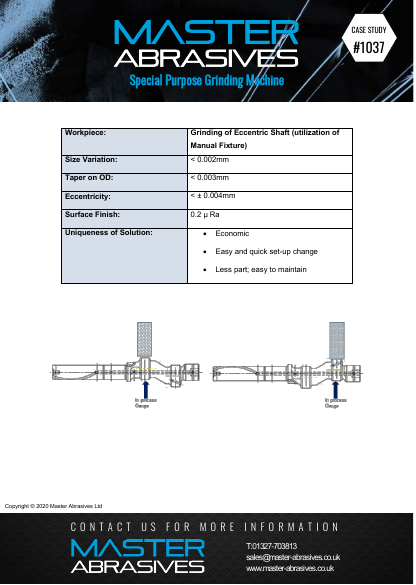

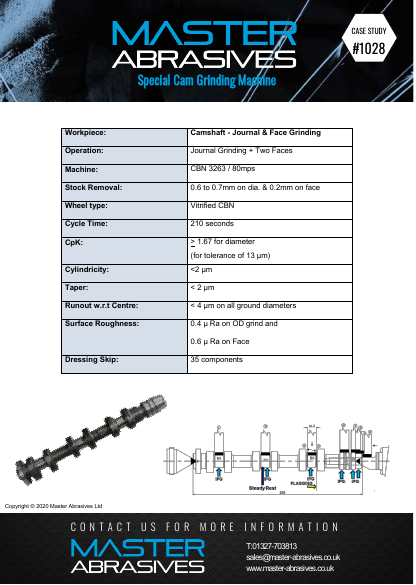

Special Purpose Grinders

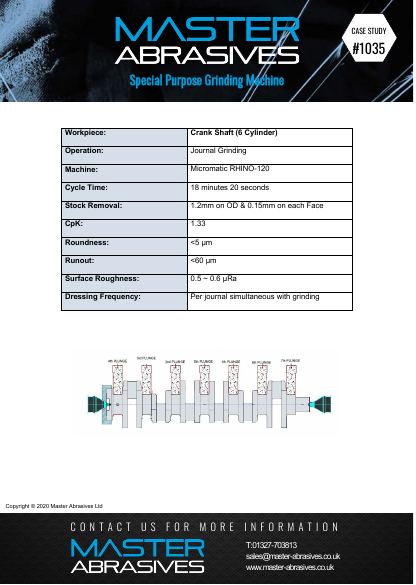

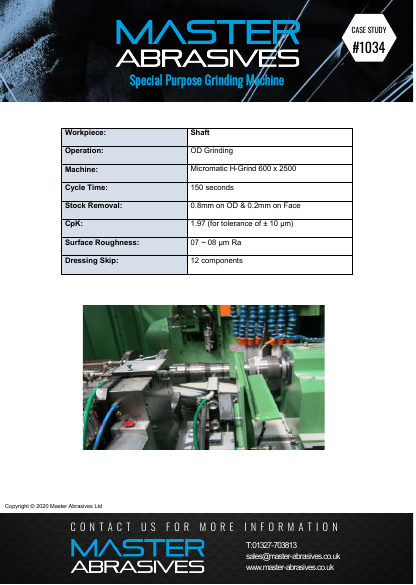

Micromatic Grinding Technologies have also developed special purpose machines by working with customers to solve application challenges. Special purpose machines have been developed indigenously by Micromatic such as:

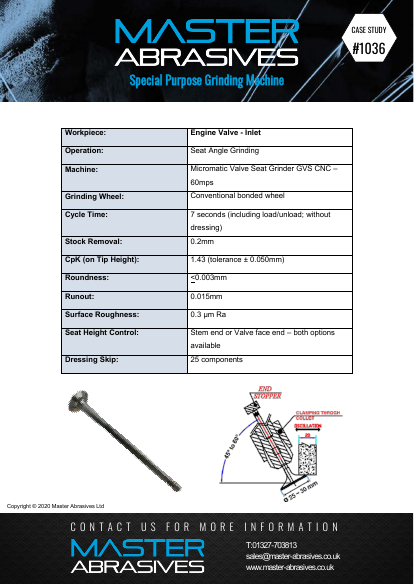

- Valve Seat Grinders

- Piston Ring Profile Grinders

- Special grinders for grinding Fuel Injection parts

Micromatic also provides automation solutions using Gantry or Robotic automation in line with customer requirements to enhance productivity. Complete system integration is achieved through their capable in-house engineering teams.

Download brochures below for more information on the range of machines available.