All of our Latest News

After 45 years of being part of the Meister group, in 2012, Master Abrasives became an independent UK owned company. As this year marks 10 years since the exciting development in company history, it’s a great opportunity to look back and celebrate its accomplishments.

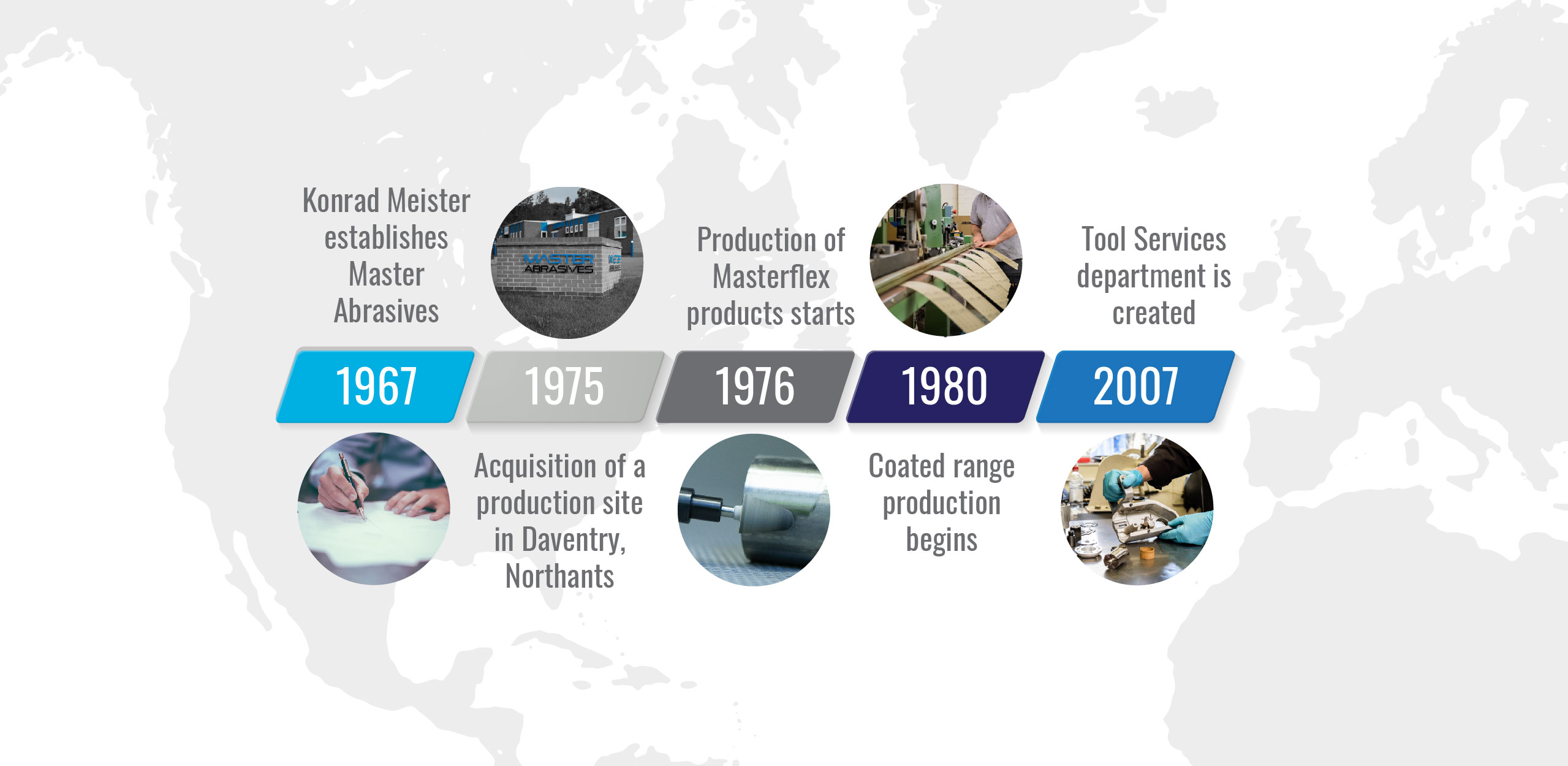

In 1967, 55 years ago, the concept of Master Abrasives was born. It was brainchild of Konrad Meister who had established his company in Switzerland (Meister Abrasives) in the early 1950’s as a seller, convertor and manufacturer of abrasive products. Konrad Meister established a subsidiary in the UK to service the aerospace and automotive markets where competitors’ slim mounted point offerings at the time provided him with a real chance of breaking in and developing a reputation for a high-quality Swiss-made products held in stock in the UK for immediate delivery. He named the company Master as a direct translation from his name Meister.

The strategy proved to be successful as it was not long before Meister became established in the UK. The foundations were laid in the first 10 years and the company built on this by offering applications engineering expertise to the automotive, bearing and fuel injection industries.

To build on the early success and rapid growth, the company invested in a site with development potential. In 1975, they purchased a unit on a prime site in Daventry and in 1979, this was developed further by building a warehouse and manufacturing unit adjacent to the main building. In 1990, the neighbouring site decided to sell, giving Master the opportunity to step up to a three-building complex incorporating admin offices, showrooms, conference facilities, warehousing and production departments – where Master Abrasives is still located today.

Expanding its product offering to meet customer needs, in the 1970’s the company developed Masterflex surface finishing products to be manufactured on-site and in the 1980’s installed a new coated abrasive conversion plant for belts. It was the 80’s and 90’s when the Meister group established a reputation in Europe and the USA for precision internal grinding, whilst in the UK, market penetration continued to grow. Overall, a strong reputation for excellence in product and applications engineering was being built, the Master team being an intrinsic part of the Meister global development.

In 2007, Master took the opportunity to provide additional services to their existing customers of pneumatic power tools following the introduction of new Health and Safety legislation around Hand-arm vibration issues. After obtaining a significant market share of power tool business alongside the key product development of mounted points, as well as developing new services such as HAV testing, Master Tool Services initiative was launched. Master embarked on the expansion of a full range of products and services to meet the increasing need.

In February 2012 Thomas Meister, the Chairman of the group, offered the opportunity for a management buyout and in December 2012, Master became an independent, UK owned company, being purchased by the current owners.

It was clear to the new owners that to survive and flourish in the current marketplace, Master Abrasives needed a strong brand identity of its own and a complete range of products under its label that would be both technically capable and marketable globally. The following year, the new own-name brand was launched alongside the existing portfolio and in 2016 the Master® trademark was registered in the UK and EU.

It was clear to the new owners that to survive and flourish in the current marketplace, Master Abrasives needed a strong brand identity of its own and a complete range of products under its label that would be both technically capable and marketable globally. The following year, the new own-name brand was launched alongside the existing portfolio and in 2016 the Master® trademark was registered in the UK and EU.

Since gaining independence, the company has gone from strength to strength. Developing some longstanding partnerships, some newer relationships around the world and its own solid Master brand has reinforced its reputation for excellent customer service, high-quality products, engineering support and technical development.

In 2019, Master Abrasives owners decided to conclude the distribution contract with Meister to enable more flexibility for international growth than the agreement would allow. Although a difficult decision to take after such a long and fruitful period for both parties, it was the right one for Master.

In the same year, its first sister company, Master Abrasives Polska Sp. z o.o., was established in Poland. It was clear to the management team that Brexit would produce some serious challenges and this, in conjunction with the objective to have a trading base in Europe to service the developing business there, led to establishment of the Polish division in Bielsko Biala. This has proved to be an inspired move for Master as the division is already making a name for itself in the marketplace.

In 2020, Master Abrasives México, officially Abrasivos Maestros Norteamerica, S.A. de C.V., was established in Mexico as a new sister company. Mexico has been a developing market for Master in recent years, with some key engineering manufacturers there praising the company for its excellent technical support, applications engineering and competitive pricing for bonded abrasive products which have proved to be consistent in quality. Master has a well-established company there incorporating premises for office and stockholding, thus providing short and reactive deliveries.

Now in 2022, some fifty-five years after its formation, Master will celebrate another milestone in their history: ten years of being an independent company in control of its own business future. The fact that Master is still thriving and looking for new opportunities is testament to the company’s resilience and foresight as well as the quality of its dedicated workforce and management team. Master continues to look forward with optimism.

Paul Batson, Master Abrasives Managing Director for the past nine years, commented, “we have gone through a lot of changes, but our objective was clear from the start: to become a strong independent abrasive company with a solid brand identity, which I believe we have achieved. I am a firm believer in having a marketing orientated approach to running a business - listening to customers and engaging with them to work together on a solution or improvement in their productivity. Added to this, the use of the latest social media platforms to engage and have a two-way communication along with a great team working together has been critical to seeing not only our survival through the recent tough times but our continued growth.”

It would not be fitting to document the history of Master without a final acknowledgement of the architect and founder of the business. Sadly, in 2016, the abrasives industry lost an entrepreneur, a pioneer, and an icon in the passing of Konrad Meister at the age of 84. Master is proud to have played its part in the development of the Meister company in the earlier years and believes Konrad’s pioneering spirit lives on in Master today, as it independently continues with its philosophy of producing a solution for industry worldwide in serving customers needs today!

We’re pleased to announce that T/Blok Ltd is now our partner in Bulgaria!

With over 20 years of extensive practical experience in the field of grinding and polishing, T/Blok converts abrasive belts in their facility and will now offer the Master high-quality range of abrasive products, such as:

- Carbide burrs

- Mounted points

- Masterflex

- Grinding wheels

- ZIPP Air tools

Visit the T/Blok website for more information about the company or to contact them.