All of our Latest News

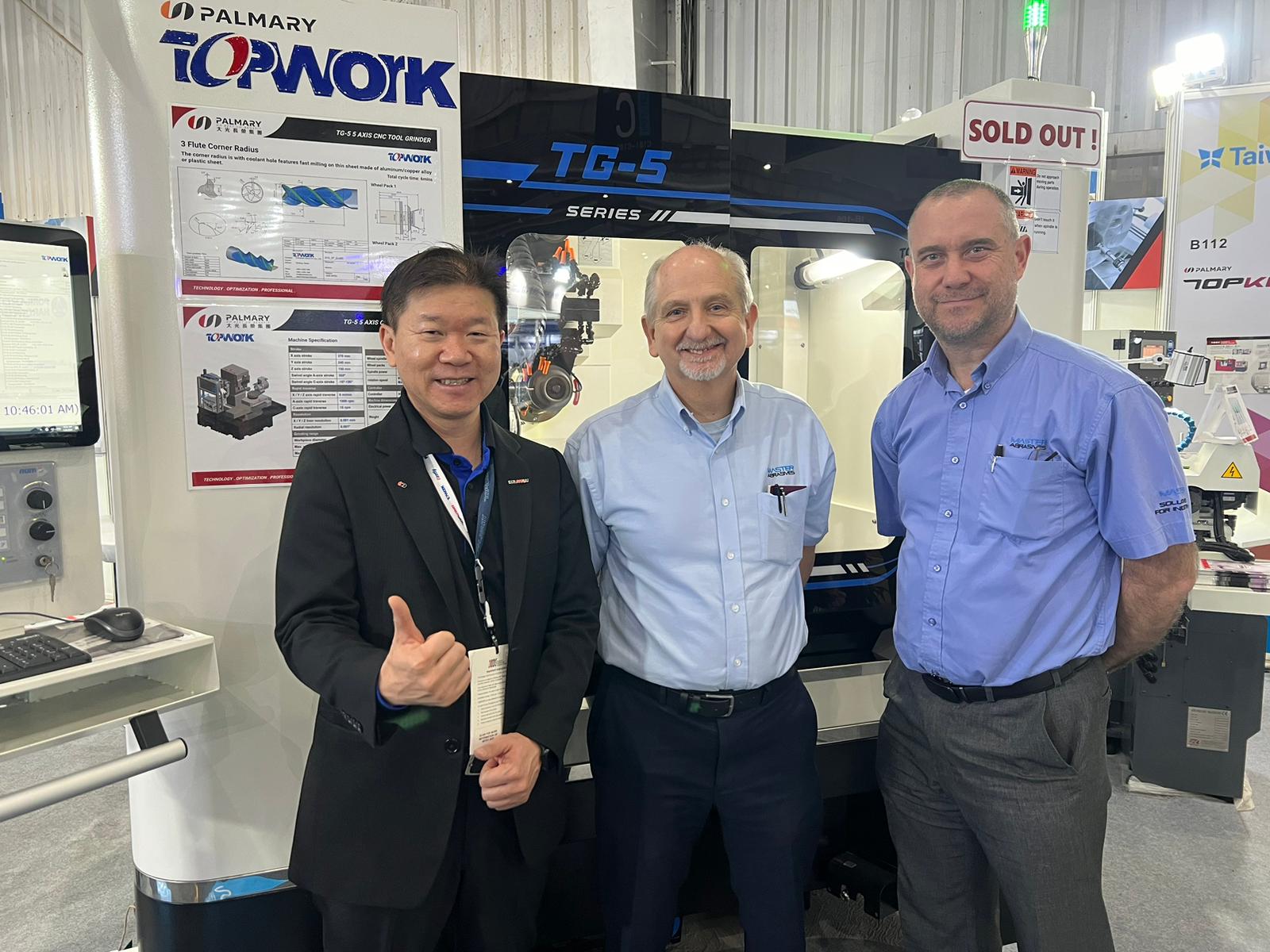

Master Abrasives' Paul Batson, Managing Director, and Ian Meredith, Applications Engineering Manager, had the opportunity to connect with Mr. Hung, General Manager at Top-Work Industrial Co Ltd., and see their cutting-edge machinery at their stand at IMTEX 2025.

Master Abrasives was appointed official UK and Ireland agent for Top-Work Industrial Co. Ltd on 1st of January 2025. Top-Work, a leading Taiwanese manufacturer of tool grinders, is renowned for its high-quality machines.

Master Abrasives has expanded its superabrasive product offering with the launch of a more comprehensive Master Vitrified CBN Abrasives range, complementing its existing high-precision external and internal grinding wheels. This new range is designed to meet the demands of manufacturers grinding high-precision components that have tight geometrical and dimensional tolerances and difficult-to-grind materials, with the added capability to process bore sizes as small as 1mm.

The range includes high-performance vitrified CBN wheels mounted on precision threaded or tungsten carbide shanks, ideal for the grinding of a variety of challenging materials found in such industries as aerospace, fuel injection, bearing, Formula One and many other high precision applications. This new addition strengthens Master Abrasives' reputation as a trusted supplier of quality abrasives and superabrasive products, offering global support to manufacturers looking to improve productivity.

Paul Batson, Managing Director of Master Abrasives, commented: "With over 50 years of industry experience, we have the expertise to assess and match the right product to each application, ensuring customers achieve the most efficient and effective processes. This ultimately results in high-quality products, competitive pricing, and maximum productivity. Our new CBN range, developed under the Master brand, is already gaining recognition internationally for its quality. We’re excited to work with new customers in 2025 to help them reach their grinding and finishing goals and achieve optimum performance from their machinery."

The steps taken to optimise the grinding process taken by Master Abrasives’ application support team aim to develop an engineered wheel specification that matches the wheel grade and size to the equipment capabilities. This includes considering factors such as speed available, power, coolant, and the dynamic and static stiffness of the machine spindle and the machine tool generally.

Another important consideration is the dressing tool and its parameters, which can significantly impact wheel performance. Master Abrasives now offers vitrified CBN specifications engineered to work well with stationary dressing tools. Master’s engineers can provide recommendations to optimise the use of Master wheels by fine-tuning machine settings, coolant, speeds, feeds, and dressing parameters.

As part of the launch, Master Abrasives will continue to offer its established range of alternative superabrasive bond systems and auxiliary products, such as precision diamond dresser and grinding quills, to bring a comprehensive package for manufacturers across various industries.

For further details about the superabrasive products Master Abrasives offers, customers can contact Master’s technical representatives for expert advice on applications and products.

Midlands-based Master Abrasives has been appointed the authorised agent for Top-Work Industrial Co.Ltd in the UK and Ireland. Top-Work, a leading Taiwanese manufacturer of tool grinders, is renowned for its high-quality machines.

Master Abrasives Managing Director, Paul Batson, visited Taiwan last year to solidify the partnership, which was officially launched on 1st January 2025.

Top-Work, founded in 1986, is a specialist in tool grinder manufacturing. The company is CE certified and has won research and development awards from Taiwan’s Industrial Bureau for three consecutive years. In 2017, Top-Work joined the Palmary Group and introduced the European NUMROTO tool grinding software.

Master Abrasives is initially highlighting two Top-Work grinding machines for the UK and Irish markets: the TP-4 Precision CNC Pinch/Peel Grinding Machine and the TD Series Diamond/CBN Wheel Truing and Dressing Machine.

TP-4 Precision CNC Pinch/Peel Grinding Machine

The TP-4 is a high-precision CNC cylindrical pinch/peel grinder with smart technology. It features two grinding wheels that operate simultaneously, enabling the grinding of cylindrical materials such as cutting tools and form punches. The TP-4 is used after centreless grinding and before the pre-processing stage on a 5-axis tool grinder. It has been successfully employed in several industries, primarily the high-precision tool industry, mold making, and the electronics and medical parts sectors.

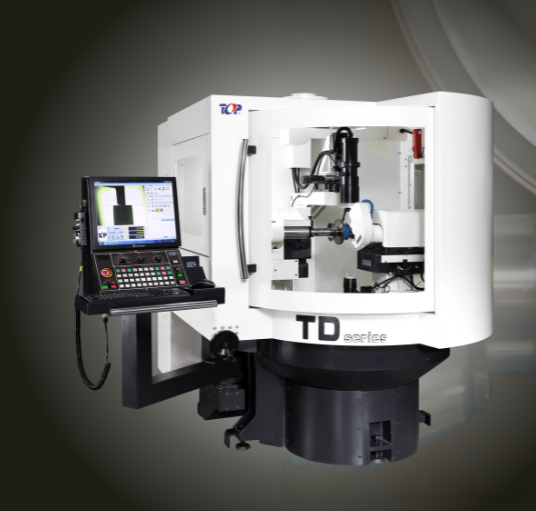

TD Series Diamond/CBN Wheel Truing and Dressing Machine

The TD Series is a high-precision machine for truing and dressing superabrasive wheels, commonly used in the cutting tool industry. The range covers straight, angled, and radiused wheels (50-250mm in diameter). Dressing wheels on their arbors from multi-axis grinding machines offers the advantages of improved cutting edges and extended wheel life. The TD machines are available in two versions: the TD-3, which features PLC control and open guarding, and the TD-5, which is fully enclosed with CNC control for enhanced safety and precision.

Paul Batson and Ian Meredith, Master Abrasives' Applications Engineering Manager, plan to attend TIMTOS in March 2025. They will collaborate further with Top-Work at Taiwan's largest machine and engineering trade show and engage with other partners exhibiting there.

Ian Meredith, who has extensive experience in the tool manufacturing industry, is particularly excited about this new addition to the Master Abrasives range. "This is a great opportunity for Master to offer cutting-edge, high-precision grinding solutions to the UK and Irish markets for tool and cutter," Ian commented. "With my background in the tool manufacturing sector, I’m delighted to be driving this side of the business and believe Top-Work grinders will make a significant impact, bringing advanced technology and performance to our customers."

For more information about the tool and cutter machinery Master Abrasives is bringing to the UK and Irish markets, customers can contact Master’s technical representatives for expert advice on products and services. Stay updated by following Master Abrasives on social media or visiting their news page at www.master-abrasives.co.uk.